- Home

- /

- By Process

- /

- Corona Treatment

Corona Treatment Process

Corona treatment system is a very effective way to increase the surface tension of virtually any material. Surface treatment is required for plastic films/fabrics whose normal surface tension is not sufficiently high to permit good wetting by flexo graphic inks. Corona treatment system increases the surface tension of the fabrics respective to inks by inducing molecular changes in the surface of the films. This is done by exposing the air at the material's surface to a high-voltage electrical discharge - a corona. Corona discharge treatment at atmospheric pressure for improving adhesion of various polymer substrate is now standard practice. Corona Treatment on Woven Fabric; laminated or un laminated (HDPE / PP) increases surface bonding strength by creating polar molecule on the surface. Also, Woven Sack Treater is used to treat separate HDPE / PP Woven Sacks or Rolls prior to printing.

Corona Treatment Process

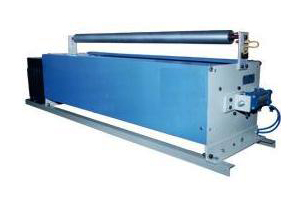

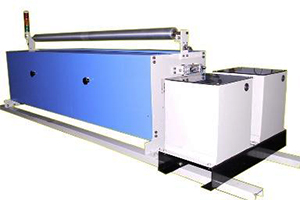

Corona Treatment Process Machinery

Corona Treatment

Our product range are Bare Roller Treater ( for Aluminum Foil / conductive films Corona Treatment with Ceramic Electrodes ) , Narrow Web Treaters , Corona Treater Machine and Corona Treater Systems for Blown Film Extrusion Plants for Monolayer and High Speed Multilayer plants, On-Line Corona Treater for Rotogravure / Flexo-printing machines, Woven Sack Roll Printing, and serving different industries. Our Range of Products: Corona Treater, Corona Treatment System, Corona Generator, Blown Film, Corona Treater, Narrow Web Treater, Bare Roller Treater