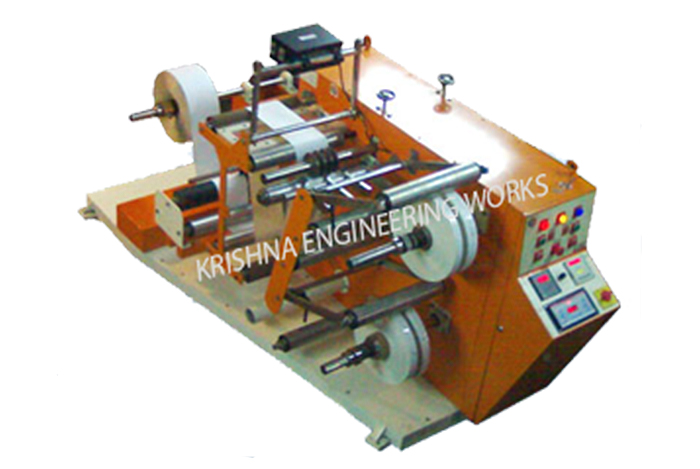

Doctoring Rewinding Machine With Slitting System

We are designed and built doctoring inspection machine with Inspection mounting facility, slitting Arrangement, single wall cantilevered construction. All Label Manufacturers require slitting of Jumbo Rolls to individual Label Rolls. Big Label Converters require slitting of Jumbo Rolls into smaller Rolls after printing in Flexo Printing Machine. Generally in use of Inspection and slitting of all types of material like Plastic, Paper, Flexible Packaging, PVC, Aluminum Foil, Stretch Film, LDPE Film, BOPP Film, BOPP Tape and many more. Doctoring Rewinding Machine, Inspection facility of perfect slitting of rolls with consistent quality and constant line speed.

Doctoring Rewinding Machine With Slitting System

- Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner).

- Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer.

- Provision for incorporating Inkjet Printing System with Hot air ink drying.

- The Model is specially designed for correcting badly wounded reels for inspection & doctoring operation.

- It is great substitute to online coding / batching operation

- Convenient height for operation

- Compact Design

- Variable speed drive

- Double drive

| Technical Specification of Machine: | |

|---|---|

| Web width | 100 to 1500 MM |

| Max. Weight of Unwind | 100 to 1000 KG (Different models for different weight) |

| Max. Parent Reel Dia. | 400 MM |

| Max. Rewind Reel Dia. | 400 MM |

| Rewind Core Dia. | 76 MM |

| Motor | 2 HP AC / DC Motor (3, 5 HP also available on suitable model) |

| Maximum Designed Speed | 100 to 150 Mtrs / Min |

Send Inquiry